Description of BORUSA

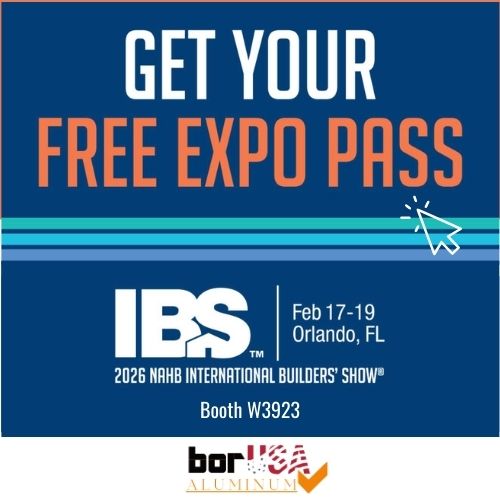

BORUSA is one of the biggest aluminum extrusion profile manufacturers. Our warehouse in the US is situated in Orlando, Florida and our production plants are in Turkey. We are holders of prestigious certificates such as qualia, and calanoid. BORUSA is one of the leading aluminum extruders with high-tech-based manufacturing plants situated on 700.000 sq ft of land including plants of billed casting, extrusion, electrostatic powder coating, anodic oxidation, and mechanical treatment.

At the moment, BORUSA is one of the leading producers of aluminum billets and customized aluminum profiles in the market. We offer a cost-efficient and high-standard products by manufacturing in our plants in Turkey and by supplying to the clients from our warehouse in Orlando, Florida state.

We have been importing to the USA and EU for many years. Therefore, we have specialized in the market needs of the United States aluminum extrusion profiles and billet industry. Our business model is established on customer satisfaction, business ethics, and competitive price with the highest quality.

Aluminum Production:

- Aluminum Billet production (production capacity: 120.000.000 lbs per year)

- Four extrusion presses: 2 x 5-inch press, 1 x 7-inch press, 1 x 9-inch press. Production capacity: 66.200.000 lbs per year.

- Anodizing. ( Profiles up to 43 ft can be anodized. ) Production capacity: 8.000.000 lbs per year.

- 2 Powder coating plant, vertical and four ( Profiles up to 37 ft can be coated. ) Production capacity: 42.328.754 lbs per year

- Machine Park for mechanical processing.

We offer you:

-

- Production and supply in accordance with international standards.

- Profile design and technical support from our product development department

- Truck or Container deliveries – full or partial loads flexible according to your requirements

- Fast production and supply times

- Cost-optimized production planning

- Customer satisfaction

BORUSA / Aluminum Profiles

Best regards.

Bor Aluminum – Content Producer