What are the Types of Aluminum?

Aluminum is one of the world’s most common metals and has a wide range of industrial uses.

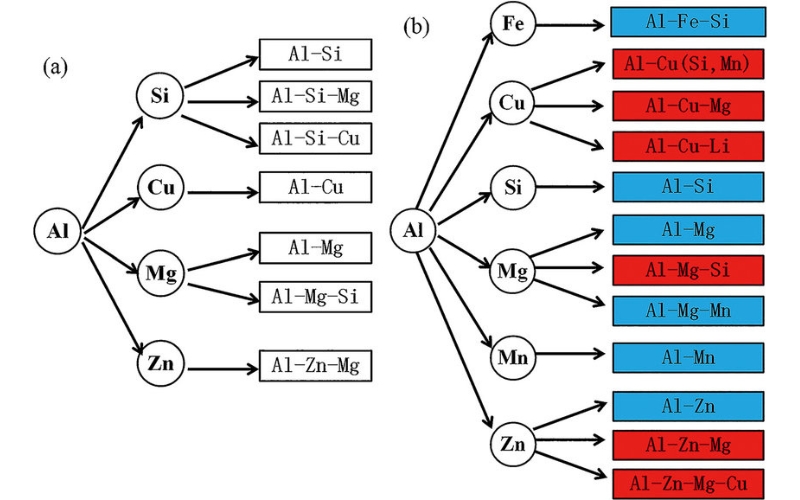

The mechanical, physical and chemical properties of aluminum alloys vary depending on the alloying elements and microstructure. The most important alloying elements added to aluminum are copper, manganese, silicon, magnesium and zinc.

There are varieties of aluminum with different properties and each one is ideal for different applications. In this article, we will focus on the different varieties of aluminum and the properties of each.

As Bor Aluminum USA, we use the highest quality aluminum varieties to produce aluminum profiles. We also undertake the mission of zero error in production by using the most suitable aluminum in aluminum billet production. We are one of the best American aluminum extrusion company.

Below we have left a content that we have examined aluminum types for you.

7 Types of Aluminum Series and Alloys

Aluminum varieties consist of 7 different series. Aluminum alloys are divided into two groups as forging and casting alloys. Wrought alloys have good plastic deformation capability and can be easily shaped. Most of the aluminum forging and casting alloys can be heat treated.

Depending on the aluminum elements and heat treatments, aluminum grades can provide a wide range of properties such as appearance, ease of fabrication, good corrosion resistance, high strength-to-weight ratio, weldability and high tensile strength.

The choice of the appropriate aluminum grade depends on the desired application and operating conditions.

-

1000 Series Aluminum

1000 series aluminum is higher in purity than all other aluminum grades. It has an aluminum content of 99.00% or higher and is often used in industrial applications. Since 1000 series aluminum has good formability, it is often used in mold making and in the production of various industrial parts.

-

2000 Series Aluminum

2000 series aluminum is copper alloyed and has excellent strength properties. It is widely used in the aircraft, spacecraft and defense industries. 2000 series aluminum is also a variety that can maintain its strength at high temperatures.

-

3000 Series Aluminum

3000 series aluminum is a manganese alloy and is a combination of strength and corrosion resistance. It is widely used in the automotive, construction and electrical industries. 3000 series aluminum is also suitable for welding.

-

4000 Series Aluminum

4000 series aluminum is a silicon alloy and is ideal for welding. This variety is used in the production of high strength alloys. In particular, 4043 aluminum is often used in welding wires and aluminum sheet metal.

-

5000 Series Aluminum

5000 series aluminum is magnesium alloyed and combines strength and corrosion resistance. It is commonly used in the marine, construction and automotive industries. 5000 series aluminum is also resistant to high temperatures and is often used in furnaces or other applications exposed to high heat.

-

6000 Series Aluminum

6000 series aluminum is alloyed with magnesium and silicon and has excellent strength properties. This type of aluminum is commonly used in the construction, automotive and aerospace industries. 6061 and 6063 aluminum alloys are the most common 6000 series aluminum grades and are often used as pipe, profile and cladding material.

-

7000 Series Aluminum

7000 series aluminum is zinc alloyed and has excellent strength properties. This kind of aluminum is widely used in the aerospace, spacecraft and defense industries. 7075 aluminum alloy is one of the most common varieties of 7000 series aluminum and has high strength and durability properties.

Each aluminum variety has its own unique properties and is ideal for different applications. These properties explain why the industrial use of aluminum is so widespread. Aluminum is one of the most important materials of modern industry due to its low density, corrosion resistant, excellent strength properties and wide range of applications.

Bor Aluminum – Content Producer