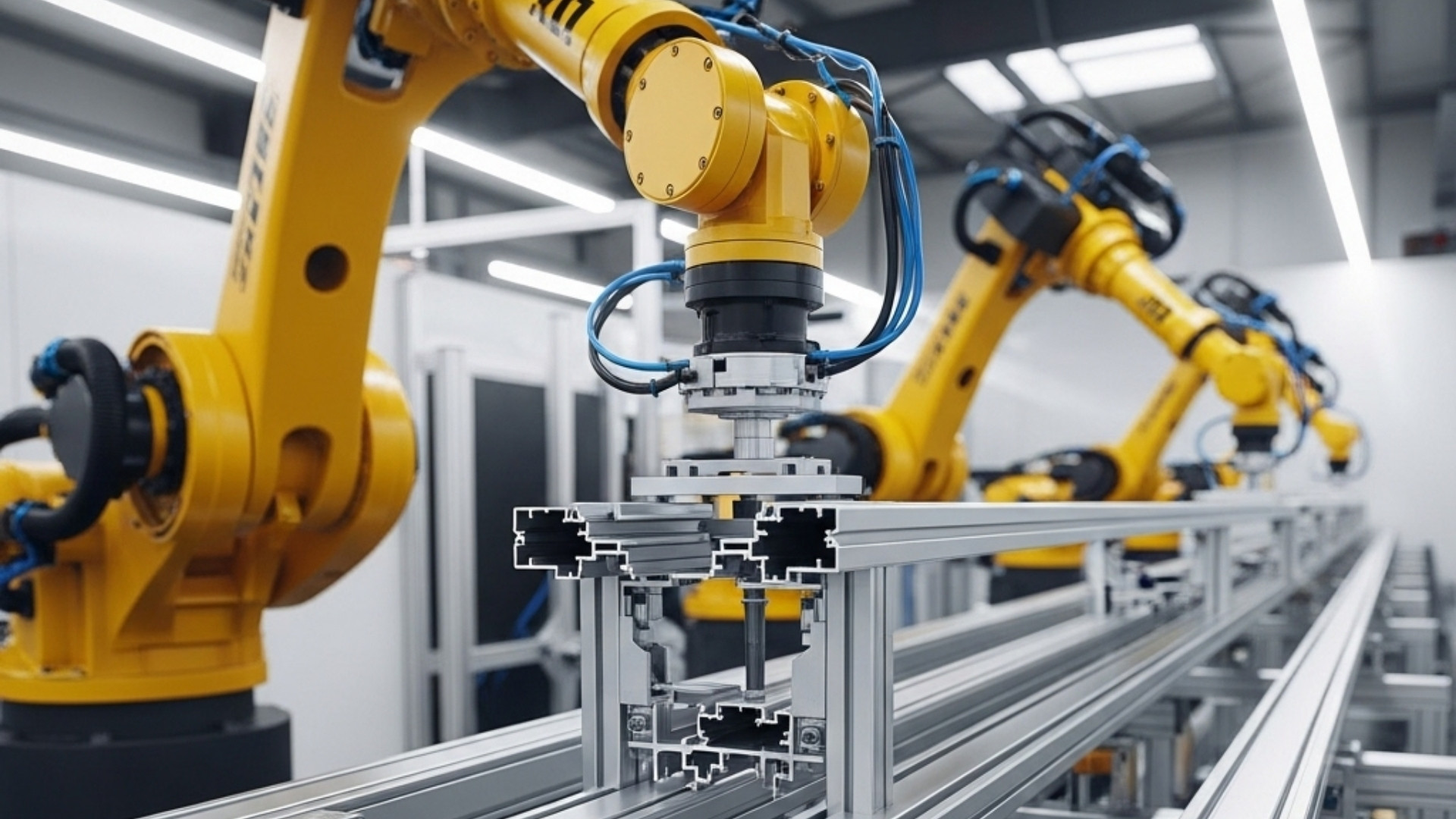

Lightweight Aluminum Profiles for Robotic Production Lines

Robotic production lines are the backbone of modern industrial manufacturing. These systems stand out with their precision, speed, and energy efficiency—driving higher productivity across various sectors. However, to operate efficiently, these lines must be constructed with high-quality, technologically compatible materials. This is where BOR USA delivers a distinct advantage through its lightweight and flexible aluminum extrusion profiles USA solutions.

BOR USA’s specialized aluminium profiles enable smooth automation and robotic integration in production facilities. The use of aluminum profiles not only enhances operational efficiency but also ensures durability and structural quality for long-term usage.

Why Do Robotic Systems Require Lightweight and Flexible Structures?

Robotic production systems are composed of numerous moving and load-bearing parts. To optimize performance, all these components—carriers, connectors, and frames—must be both lightweight and strong. Here’s why:

-

Lightweight materials help reduce energy consumption.

-

Flexible materials allow easy integration and system adaptation.

-

Modular design structures enable simplified maintenance and faster upgrades.

These benefits can be easily achieved through aluminum profiles, making them the ideal material for robotic production environments.

Main Areas of Application for Aluminum Profiles in Robotic Lines

As a specialist in custom aluminum profiles, BOR USA provides tailor-made solutions for a wide range of robotic automation applications. Below are the most common use cases:

-

Rail and conveyor systems

-

Body and carrier frames

-

Protective enclosures and machine housing

-

Camera and sensor mounting fixtures

-

Structural support for robotic arms

-

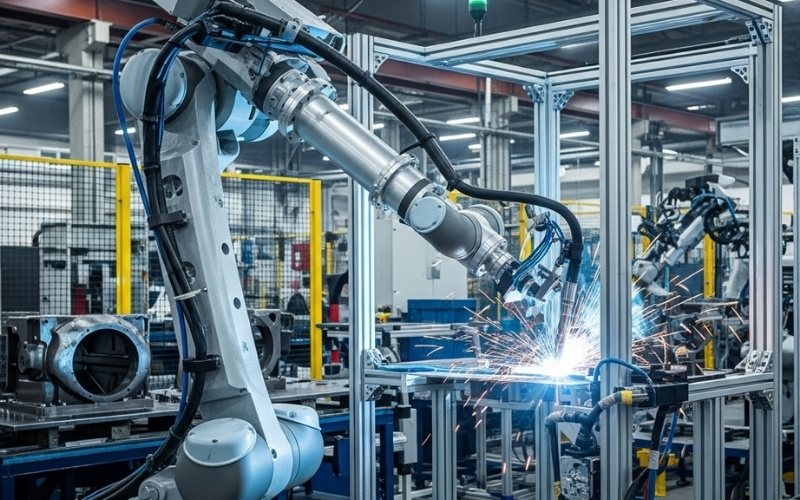

Welding, injection, and assembly stations

Corrosion-resistant aluminum extrusion profiles USA are the structural backbone in these applications, ensuring long-lasting performance even under continuous motion and exposure to industrial environments.

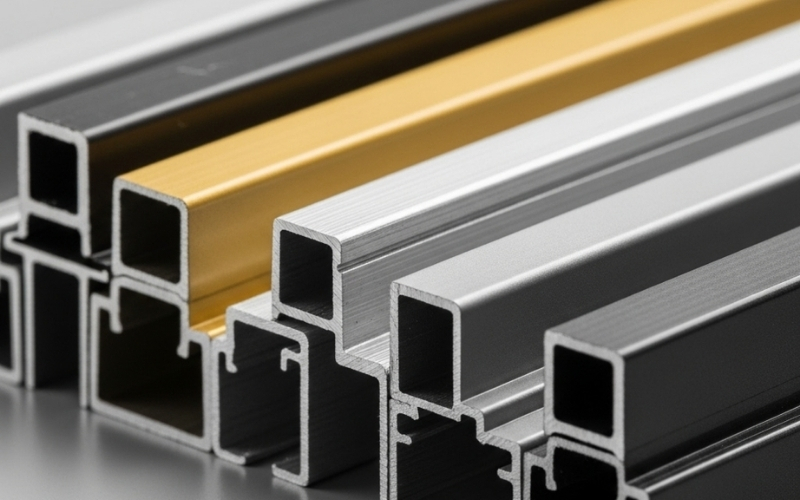

Project-Specific and Modular Aluminum Solutions with BOR USA

Every robotic production line is unique, which is why BOR USA offers project-based aluminum profile solutions designed to fit your specific needs. Key advantages include:

-

High-precision manufacturing with minimal tolerances

-

Technical drawing support for custom-designed profiles

-

Anodized and powder-coated surface treatments for enhanced durability

-

Fast delivery timelines and expert engineering assistance

-

Modular systems that support flexible and scalable designs

By working with BOR USA, you can elevate the functionality and visual appeal of your production lines with efficient, long-lasting aluminium profile systems.

A Reliable Partner in Robotic Production: BOR USA

BOR USA is your trusted partner for aluminum profile needs, combining engineering excellence with production flexibility. Our company stands out in the aluminum extrusion profiles USA market by offering:

-

Tailored solutions for robotic and industrial systems

-

Superior quality control and precision manufacturing

-

Environmentally friendly and sustainable production practices

-

Expert technical support from design to delivery

Whether you are upgrading your existing automation system or building a new robotic line from scratch, BOR USA delivers the expertise and materials you need.

Bor Aluminum – Content Producer