It is the process of making a coating on aluminum so that aluminum does not corrode with environmental effects. Anodizing is a very special surface coating for aluminum and is obtained after a series of electrochemical processes. As the anodized layer is very hard and thus very abrasion resistant, it gives aluminum superior properties.

Why aluminum is anodized?

As you know, iron is rusted by the effect of air and water or moisture. So, does Aluminum rust? Yes, Aluminum also corrodes, that is, it undergoes corrosion. When aluminum has a certain time in nature, it is corroded by the effect of air and moisture. We need to cover small gaps on aluminum so that aluminum does not corrode and weather conditions do not spoil aluminum.

Aluminum Anodized Made For What?

Aluminum is made of anodized aluminum parts and aluminum profiles.

Aluminum parts; automotive aluminum parts, handrail parts, electronic circuit components, aluminum aircraft parts, aluminum balustrades, and many more.

Aluminum anodized is divided into two in this context. The first one is anodized, and the other one is profile-sized anodized. The lengths of anodizing pools are around 2-3-4 meters in anodized aluminum parts. In the places where the aluminum profile is anodized, the lengths of aluminum anodized pools are around 6-7-8 and 9 meters due to their profile lengths. Depending on how it is made, aluminum anodized is made in two ways.

- Horizontal aluminum anodized

- Vertical aluminum anodized

Horizontal aluminum anodized

How is Horizontal Aluminum anodized made?

The anodized shape in which the aluminum anodized pools extend horizontally is called horizontally anodized.

The advantages of horizontal aluminum anodizing are more. Besides, the investment cost is more appropriate.

What are the advantages of Aluminum Horizontal Anodized?

- The investment cost is 3-4 times cheaper than vertical anodizing.

- The lower and upper side difference problem encountered in aluminum vertical anodizing does not occur in horizontal anodizing.

- The material used in Aluminum Horizontal Anodizing is less.

Vertical Aluminum anodized

How is Vertical Aluminum anodized made?

The anodized shape in which the aluminum anodized pools are vertical is called vertically anodized. The advantages of vertical aluminum anodized are as follows:

Advantages of Vertical Aluminum Anodized

First, less manpower is used when loading and unloading aluminum profiles.

Environmental contamination is less during the anodizing process.

Since aluminum-anodized liquids and chemicals are easier to drip and filter from the profile after aluminum anodizing and similar processes, it can be easily changed from one process to another.

Vertical anodizing is more advantageous if it is to be produced in multiple productions, ie thousands from the same profile. However, if the aluminum profile is to be changed without stopping and there is an anodized aluminum profile in small batches, the vertical anodizing is not much logical. Because the vertical anodizing process is always troublesome.

Disadvantages of Vertical Aluminum Anodized

- The investment cost varies from business to business and is 3-4 times more.

For example, if the horizontal aluminum anodizing facility can be established with prices starting from 1.5 Million Euros, vertical aluminum anodizing can not be installed below 4-5 Million Euros.

Mechanical brightness processes before aluminum anodizing and surface treatment after sandblasting will be affected during transportation and similar processes, and surface quality problems will arise.

- The production cost is affected and higher than the similar horizontal aluminum anodized:

- The electrical energy consumption in the aluminum anodizing pool and the electricity consumption in the aluminum electro-color tank is higher due to the long-range cathodes.

Chemical consumption in condensation tanks in aluminum vertical anodizing is quite high. Because anodizing and liquids in tanks have to be used almost twice.

- Unlike aluminum horizontal anodizing, aluminum vertical anodizing heating and cooling tanks are two times larger.

Because of the size of the aluminum anodized pools, cooling and heating cost almost twice as much energy.

Aluminum anodizing clamping pins, also called jigs, are more expensive in vertical anodizing than horizontal anodizing. Therefore, if the vertical anodized pliers, that is, anodized pliers, are broken, they are more costly to repair and renew.

- Maintenance costs of holding systems in aluminum anodizing are also quite high.

In aluminum horizontal anodized, the movement of the crane between pools is slower. The other is faster.

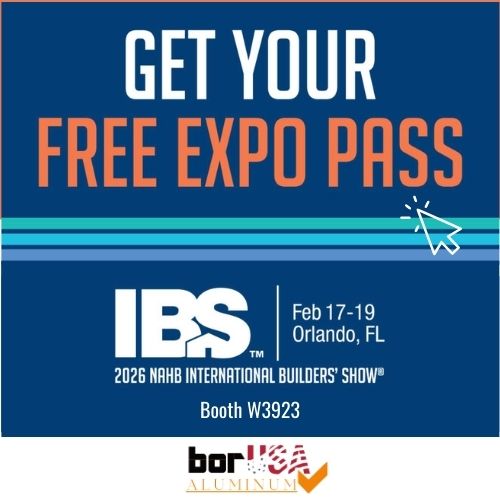

So if you are looking for an aluminum extrusion profile manufacturer and aluminum billet manufacturer please contact Billet manufacturer BOR Aluminum for more information.

Bor Aluminum – Content Producer