Custom Billet Casting for Aluminum Extrusion Lines – Precision Solutions by BOR USA

Extrusion manufacturers in the US market are increasingly seeking customized solutions for their production lines instead of standard billets. As a result, searches for “custom billet casting for aluminum extrusion lines” on Google are steadily increasing.

BOR USA is an experienced company that stands out with its custom billet casting solutions specifically developed for aluminum extrusion lines. Through its advanced billet casting infrastructure, BOR USA supports extrusion manufacturers with high-performance, line-specific billet solutions.

Aluminum alloy selection for industries Click to learn!

Anodized aluminum display systems Click to learn!

Durable Aluminum Extrusion Profiles for 5G and 5.5G Infrastructures Click to learn!

What Makes Custom Billet Casting Critical for Extrusion Performance

No two extrusion lines are the same. Die design, press capacity, cooling systems, and the type of profile to be produced directly affect billet performance. BOR USA’s custom billet casting approach is designed to maximize the efficiency, stability, and output quality of extrusion lines.

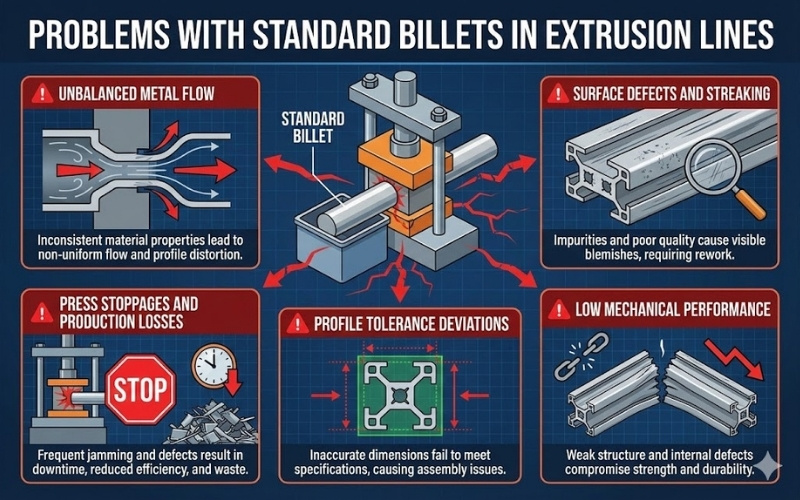

Problems with Standard Billets in Extrusion Lines

- Unbalanced metal flow

- Surface defects and streaking

- Press stoppages and production losses

- Profile tolerance deviations

- Low mechanical performance

These issues typically arise from billets that are not produced specifically for the technical requirements of extrusion lines.

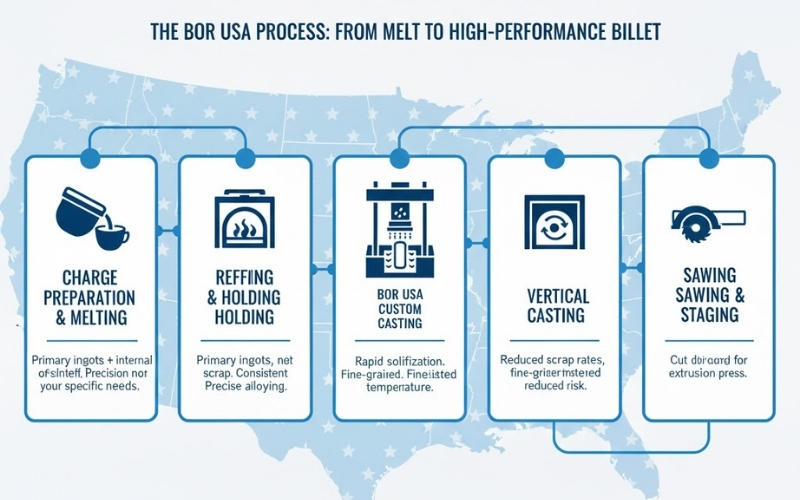

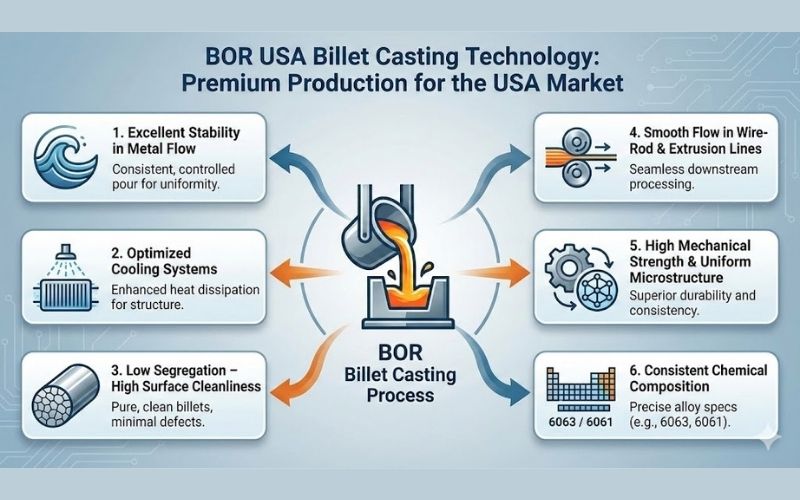

BOR USA’s Custom Billet Casting Technology

BOR USA applies billet production processes that are specifically engineered for extrusion lines within its advanced billet casting operations. This approach is one of the strongest factors that differentiates BOR USA from standard billet suppliers in the US market.

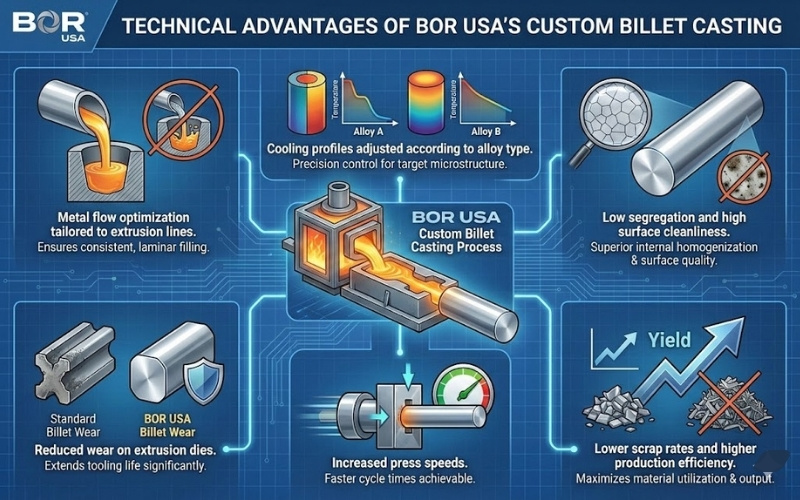

Technical Advantages of BOR USA’s Custom Billet Casting

- Metal flow optimization tailored to extrusion lines

- Cooling profiles adjusted according to alloy type

- Low segregation and high surface cleanliness

- Reduced wear on extrusion dies

- Increased press speeds

- Lower scrap rates and higher production efficiency

BOR USA’s custom billet casting solutions—especially for 6063 and 6061 alloys—ensure stable, trouble-free, and consistent performance in aluminum extrusion lines.

Why USA Extrusion Manufacturers Choose BOR USA

Extrusion manufacturers in the USA choose BOR USA when searching for “custom billet casting for aluminum extrusion lines” because BOR USA does not simply supply billets; it delivers engineering-driven solutions that directly optimize extrusion performance.

Value BOR USA Delivers to American Buyers

- Line-specific billet production

- Consistent chemical composition

- Long-term quality stability

- USA-compliant logistics and shipment planning

- Project-based MOQ flexibility

By combining Turkey’s advanced billet casting expertise with a USA-focused supply approach, BOR USA aligns its production capabilities with the real needs of the American extrusion industry.

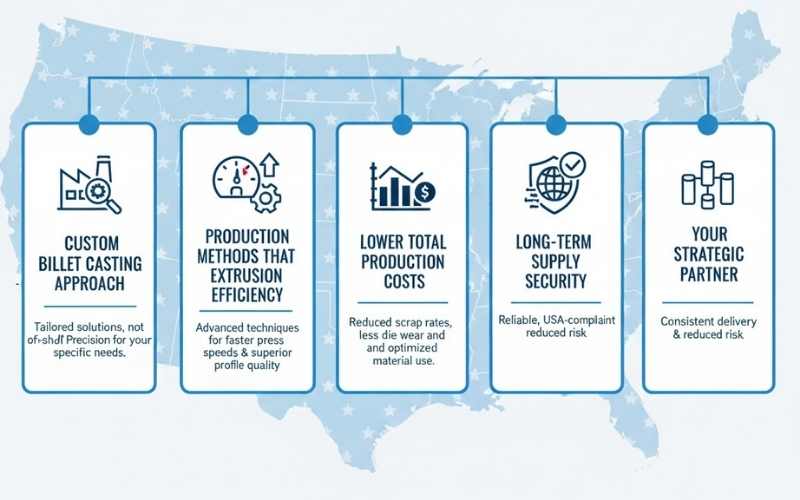

BOR USA vs Standard Billet Suppliers

Standard billet suppliers typically offer the same product to all customers. BOR USA, however, analyzes each extrusion line and adjusts alloy selection and casting parameters accordingly through its customized billet casting process.

BOR USA’s Advantage Over Competitors

- Custom billet casting approach

- Production methods that increase extrusion efficienc

- Lower total production costs

- Long-term supply security

For this reason, BOR USA is considered a strategic business partner for companies seeking a custom aluminum billet supplier in the US market.

Custom Billet Casting That Powers Extrusion Lines

For all USA-based manufacturers searching for “custom billet casting for aluminum extrusion lines,” BOR USA represents the strongest solution in terms of quality, engineering expertise, and sustainable supply.

By adapting billet casting technology to the real operational needs of extrusion lines, BOR USA provides American manufacturers with a clear and measurable competitive advantage. Contact us!

FAQ – Frequently Asked Questions

- Why is custom billet casting important for extrusion lines?

Because every extrusion line has unique technical requirements, and standard billets can lead to performance losses.

- For which alloys does BOR USA provide custom billet casting?

6063, 6061, and other special alloys commonly used in the aluminum extrusion industry.

- How does custom billet casting affect extrusion performance?

It enables more stable press operation, reduces surface defects, and improves overall production efficiency.

- Is production and shipping specifically for the USA possible?

Yes. BOR USA offers USA-focused production planning and regular shipment solutions.

- What is the minimum order quantity?

MOQ is determined flexibly based on the specific project requirements and extrusion line configuration.

Bor Aluminum – Content Producer