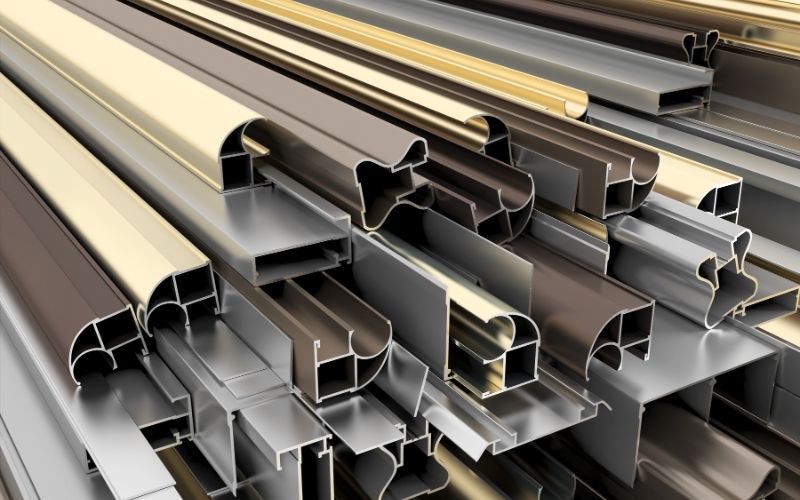

Aluminum is revolutionizing the Construction and Architecture sector by offering lightweight, durable, and cost-effective solutions. From Aluminum Channels to Anodized Aluminum finishes, these materials are designed to reduce expenses while enhancing performance. Here’s how businesses achieve significant cost savings with Aluminum Profiles

Reduced Material and Installation Costs

Aluminum profiles are inherently lightweight compared to traditional materials like steel. This translates to:

- Lower transportation costs: Lighter loads mean fewer trips and reduced fuel expenses.

- Faster, easier installation: Aluminum channels and extrusions can be assembled quickly with minimal labor, cutting down on construction timelines and labor costs.

- Precision engineering: Customizable aluminum profiles reduce material waste, as they’re manufactured to exact project specifications.

Aluminum Profiles The Foundation of Modern Cost-Efficient Construction

Aluminum Profiles are engineered to optimize budgets without compromising quality. Their unique properties make them ideal for the Construction and Architecture sector:

- Lightweight design reduces transportation and labor costs.

- Precision extrusion minimizes material waste during manufacturing.

- Modular assembly slashes installation time and complexity.

By replacing heavier materials like steel, Aluminum Profiles cut project costs by up to 25% while maintaining structural integrity.

Aluminum Channels Streamlining Design and Installation Costs

Aluminum Channels are a versatile subset of Aluminum Profiles that simplify construction workflows:

- Prefabricated designs: Ready-to-install Aluminum Channels eliminate costly on-site fabrication.

- Thermal efficiency: Their natural conductivity reduces the need for additional cooling systems in buildings.

- Adaptability: Customizable shapes fit diverse architectural needs, from façades to interior frameworks.

For example, using Aluminum Channels in curtain wall systems can lower installation costs by 30% compared to traditional steel.

Anodized Aluminum: Durability That Reduces Long-Term Expenses

Anodized Aluminum is a premium choice for the Construction and Architecture sector due to its unmatched longevity:

- Corrosion resistance: Withstands harsh weather, eliminating costly maintenance or replacements.

- Aesthetic appeal: The anodized finish requires no painting, saving up to 15% in finishing costs.

- Recyclability: Fully reusable at the end of its lifecycle, aligning with sustainable building practices.

Projects using Anodized Aluminum report 40% lower maintenance costs over a decade compared to painted steel.

Why the Construction and Architecture Sector is Embracing Aluminum

The Construction and Architecture sector is rapidly adopting Aluminum Profiles for three key reasons:

- Budget-friendly sustainability: Recycled aluminum cuts material costs by 20% while meeting LEED standards.

- Speed-to-market: Lightweight Aluminum Channels accelerate project timelines, reducing overhead.

- Design freedom: Custom Anodized Aluminum finishes enable architects to innovate without budget overruns.

A 2023 industry survey found that 68% of firms using Aluminum Profiles completed projects under budget.

Start Saving Today with Aluminum Solutions

Whether you’re designing skyscrapers or residential complexes, Aluminum Profiles, Aluminum Channels, and Anodized Aluminum offer unmatched cost efficiency. By integrating these materials, the Construction and Architecture sector can achieve:

- Lower upfront costs (15–30% savings on materials and labor).

- Reduced lifecycle expenses (minimal maintenance and replacements).

- Enhanced ROI through sustainable, future-proof designs.

Ready to cut costs on your next project? Explore our Anodized Aluminum finishes and precision-engineered Aluminum Channels tailored for the Construction and Architecture sector.

Bor Aluminum – Content Producer